- Overfill cut-out device according to § 19 WHG

- Slimline construction, width only 22.5 mm

- Adjustable sensitivity

- Potential-free output as SPDT (2 x)

- Power supply 230 V AC ±10% 48-62Hz, 24 V DC ±10% (optional)

Construction

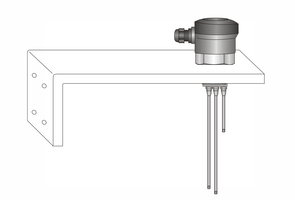

The overfill cut-out device consists of the pickup (conductive double electrode) and the electrode relay type ER-107. It provides a binary switching signal at the out-put. This signal can be sent directly or via a signal amplifier to the report device or to the control section and its control element. The overfill cut-out device's components which have no test certificate have to correspond with the sections 3 and 4 of the device's approval principles (ZG-ÜS).

Function

The electrode relay ER-107 provides a measurement voltage which makes a "working current" flow through the signal wire via the built-in resistor in the pickup. As soon as this working current is interrupted (e.g. cable break) this is detected and displayed by the ER-107 and the source contact switches to alarm status. When the filling level of the container reaches the conductive pickup's rods a measurement current is able to flow through the conductive liquid. This current, which is higher in comparison with the working current, is detected by the ER-107 and the alarm message is generated.

The sensitivity can be adjusted within the response range of the probe using a potentiometer.

The ER-107 functions are based on the closed circuit current principle. The alarm status of the relay corresponds with the dead condition of the device.

Hence, beside monitoring and reporting of wire interruptions and level increase up to the pickup's point of response, the ER-107 also monitors working current failures.

The conductive double rod electrode has a G1½" connection thread as standard.

| Allgemein | |

|---|---|

| Storage temperature | -30 °C to +80 °C |

| Operating temperature | -20 °C to +90 °C |

| Enclosure | Screw joint and head: PPH (Polypropylene) Coating: Polyamide Connection thread G 1½” Pressure 10 bar

|

| Rod material | stainless steel (1.4571) |

| Rod diameter | 4 mm |

| Rod length | 300 mm |

Double rod electrode according to §19 WHG |

|

ER 107/B |

|

| Outputs | - Contacts: 2 potential-free SPDTs (simultaneously operated) - Max. switching voltage: 250 V AC; 150 V DC - Max. switching current: 5 (3) A AC; max. 5 A DC - Switching capacity 1: 250 VA DC; 50 to 180 W DC (depending on switching voltage) |

| Inputs | - Open circuit voltage: <10 V AC - Short circuit current: <5 mA - Switching delay approx.: 0.5 s - Sensitivity range: 1 to 30 kOhm

|

| Display | 2 LED zur Signalisierung von Betrieb, Leitungsfehler und Alarm |

Z-65.13-405, Z-65.40-191 |

|

| Storage temperature | -30 °C to +80 °C |

| Operating temperature | -20 °C to +60 °C |

| Enclosure | - Weight: approx. 150 g - Protection: terminals IP20, enclosure IP40

|

| Power consumption | 1 VA |

| Power supply | 230 V AC ±10 % or 24 V DC ±10 % other voltages on request

|

Specifications subject to change.

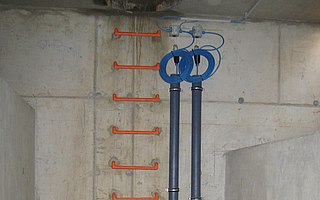

![[Translate to English:] Überfüllsicherung nach § 19 WHG [Translate to English:] Überfüllsicherung nach § 19 WHG](/fileadmin/_processed_/7/5/csm_neus-bild_9a4e457efb.jpg)