Level Sensors

NivuBar G II

Part No. HSB0 NBPX XXXX XXGHang-in probe with 1” thread and capacitive ceramic measurement cell

Submersible probe with 1” thread and 4 - 20 mA transmitter for hydrostatic level measurement in water and wastewater. Oil-free capacitive ceramic measurement cell

- Capacitive ceramic measurement cell

- heavily polluted liquids, sludge as well as pasty and corrosive media

- Large front-flush diaphragm

- 1“ thread on sensor bottom

- 2-wire probe

- Ex Zone 0

- High overpressure resistance

- Integrated overvoltage protection

This hydrostatic level probe has been developed to meet the high demands of industry and environmental protection.

The stainless steel (1.4571) probe body is locked by a capacitive ceramic measuring cell at the bottom.

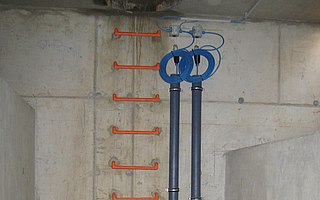

The probe is equipped with a 1“ thread at the bottom. This thread allows to extend the probe by using a protective tube. The probe then is protected against mechanical damage and the cable within the tube is protected against chemical solvents.

The non-corrosive enclosure featuring protection IP68 permits universal use for reliable determination of levels in containers, basins, shafts and tanks. The large diaphragm has proven as very reliable, particularly in the wastewater sector.

NivuBar G II features ex approval II 1G Ex ia IIC/IIB T4 for Zone 0 as standard and can be installed in any explosive area.

Utilising the widely used 2-wire technology, the installation costs are very low.

Typical applications for G II

- Pump shafts

- Grease receiving stations

- Stormwater treatment plants, storage sewers, retention tanks and discharge constructions

- WWTPs (screening control, tank levels, sludge tanks, levels in open channels)

- Industrial applications

- and many more

Data Sheet NivuBar G II

Submersible probe with thread and 4 – 20 mA transmitter for hydrostatic level measurement

Overview Pressure Probes

Overview on submersible and screw-in probes for hydrostatic level measurement

![[Translate to English:] NivuBar G II – zur hydrostatischen Füllstandsmessung [Translate to English:] NivuBar G II – zur hydrostatischen Füllstandsmessung](/fileadmin/_processed_/f/9/csm_NivuBarGII-sensor_aee88d3178.png)

![[Translate to English:] NivuBar G II mit Schutzrohrverlängerung [Translate to English:] NivuBar G II mit Schutzrohrverlängerung](/fileadmin/_processed_/3/1/csm_NivuBarGII-sensor-2_46829198eb.png)