- Ultrasonic transit time sensor for connection to NivuFlow 600 and NivuFlow 650

- High accurate monitoring of hydropower plants

- Resistant sensor material for use in various media

- Measurement in clear to slightly polluted water

- Hydropower plant monitoring with highest measurement accuracy

- For 8-path measurements according to IEC 60041 (ASME PTC 18

- Up to 100 m of cable length between sensor and transmitter or adapter box

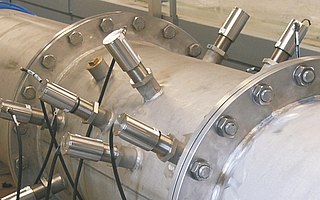

NOS screw-in sensors are part of a fixed measurement system for continuous flow measurement and storage of the recorded measurement data. They can be used for clean to slightly polluted media.

NOS screw-in sensors are used for flow measurement in full pipes featuring various dimensions.

Readings are detected based on the ultrasonic transit time principle. Creating a standardised measurement network by installing up to 8 measurement paths according to IEC 60041 allows high accurate measurement results.

Typical NOS screw-in sensor applications

- Fixed measurements in full pipes in hydropower plants, pump stations and similar

- Irrigation systems

- Inlets and outlets conducting cooling water or circulation

- WWTP outlets and many more

- Industrial flow measurements, process water, pressurised pipelines

- and many more

| Common | |

|---|---|

| Measurement principle | Ultrasonic transit time |

| Measurement range | ±20 m/s |

| Measurement frequency | 1 MHz, 200 kHz and or 500 kHz |

| Protection | IP 68 |

| Operating temperature | -20 °C to +50 °C |

| Storage temperature | −30 °C to +70 °C |

| Operating pressure | |

| Cable lengths | Up to 100 m between sensor and transmitter or adapter box |

| Medium-contacting materials | Rod sensor, Plug sensor, Screw-in sensor: Stainless steel 1.4571, CFK (Carbon), Viton® |

| Sensor connection | |

| Measurement uncertainty | Flow velocity (v average) within path ± 0.1 % of measurement value Offset velocity ± 5 mm/s

|

| Zero point drift | |

| Sensor types | |

Specifications subject to change.

![[Translate to English:] NOS Einschraubsensor für Durchflussmessung in sauberen bis leicht verschmutzten Medien [Translate to English:] NOS Einschraubsensor für Durchflussmessung in sauberen bis leicht verschmutzten Medien](/fileadmin/_processed_/4/0/csm_NOS-Srew-In-Sensor-2_67a1105a30.png)

![[Translate to English:] NOS Einschraubsensor für Durchflussmessung in Druckleitungen [Translate to English:] NOS Einschraubsensor für Durchflussmessung in Druckleitungen](/fileadmin/_processed_/c/0/csm_NOS-Srew-In-Sensor_f115a86890.png)